Pre-Engineered Steel Buildings (PEB) – Fast, Strong & Cost-Effective

M. Siddique Sons Engineering Concern (Pvt.) Ltd. is one of the leading fabricators of Pre-Engineered Steel Buildings (PEB) in Pakistan, offering customized solutions for warehouses, factories, and commercial projects.

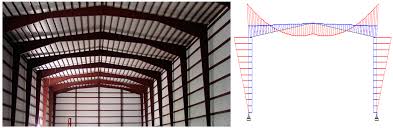

Q: What is a Pre-Engineered Steel Building (PEB)?

A Pre-Engineered Steel Building (PEB) is a modern construction system in which the main steel components are fabricated in a factory and then assembled on-site. As a result, this method speeds up the overall construction process. it ensures better quality control since the components are produced under factory conditions. the system lowers costs by reducing both labor needs and material wastage. PEBs are becoming a preferred choice over conventional concrete buildings.

At M. Siddique Sons ., we design and manufacture PEB structures that meet international standards and project-specific requirements.

Advantages of PEB Steel Structures:

-

Faster Construction: With factory-made components, PEB projects can be completed much more efficiently. As a result, construction is often 40–50% quicker than conventional buildings. Consequently, businesses save both time and resources during project execution.

-

Cost Savings: This system minimizes labor requirements and reduces material wastage, making it more economical.

-

High Durability: Strong steel frames combined with hot-dip galvanization provide long-lasting resistance against corrosion.

-

Flexible Design: Future expansions or modifications can be carried out with ease, saving time and cost.

-

Energy Efficiency: Built-in insulation options help lower cooling and energy expenses.

-

Wide Versatility: From industrial warehouses to commercial complexes and institutional buildings, PEBs are suitable for multiple applications.

Applications of PEB in Pakistan:

-

Industrial warehouses and workshops

-

Factories and production facilities

-

Logistic centers and storage units

-

Commercial buildings and showrooms

-

Educational and institutional buildings

-

Aircraft hangars and large sheds

Q:Why Choose M. Siddique Sons ?

-

In-house design team for customized PEB solutions

-

Advanced fabrication facility with quality control

-

Hot-Dip Galvanization per ASTM A123 for longer life

-

Experience in nationwide projects with timely delivery

-

End-to-end service: design, fabrication, galvanization, and installation

PEB vs Conventional Construction:

| Feature | PEB Structure | Conventional RCC Building |

|---|---|---|

| Speed | Very Fast (weeks) | Slow (months) |

| Cost | Lower overall | Higher due to labor & material |

| Flexibility | Easy expansion | Difficult & costly |

| Durability | Long life, galvanized | Requires regular maintenance |

FAQs:

Q1: How long does it take to build a PEB warehouse?

Typically 6–10 weeks depending on size and complexity.

Q2: Are PEB buildings earthquake resistant?

Yes, steel frames are flexible and designed for seismic loads.

Q3: Can PEB structures be customized?

Yes, we provide tailored designs for dimensions, cladding, and insulation.

Q4: What is the lifespan of a PEB building?

With hot-dip galvanization, PEB buildings can last 30–40 years with minimal maintenance.

Call to Action

Looking for the best Pre-Engineered Steel Building solutions in Pakistan?

Contact M. Siddique Sons Engineering Concern (Pvt.) Ltd. today for a free consultation and quotation.

👉 Visit: M. Siddique Sons Engineering Concern Pvt. Ltd.

👉 Call / WhatsApp: /

👉 Email: ahsan.bilal@ssons.com.pk / info@galvanization.pk

About the Author

Ahsan Bilal is the Marketing Manager at M. Siddique Sons Engineering Concern (Pvt.) Ltd. With years of experience in the steel fabrication and galvanization industry, he is passionate about promoting innovative solutions like Pre-Engineered Steel Buildings (PEB), Hot-Dip Galvanization, and steel structures across Pakistan.